Different pipe production requires different production requirements for pipe welding molds. For example, for small pipes, the mold design needs to be relatively compact, so that the production process will be relatively stable. The mold of the square pipe must be designed with a good angle, otherwise the size of the pipes will not meet the requirements. The requirements for the production of large diameter thick pipe welding molds are even greater.

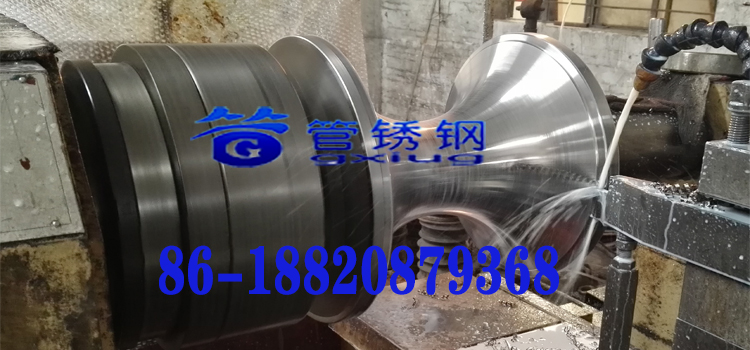

Large diameter pipe welding molds are generally used to produce metal welded pipes with a large diameter range and large thickness. The large diameter of the pipe requires a larger die size. Because the general die steel material has a limited outer diameter, the materials of large diameter pipe welding molds are special forged materials, and the cost is much higher than conventional materials. In addition, if the wall thickness of the pipe is large, this requires that the welded pipe welding mold has a strong anti-extrusion ability. It is necessary to increase the bottom diameter and side thickness of the pipe welding mold. If the bottom diameter of the pipe welding mold is increased, the roller of the pipe welding machine fits better. Otherwise, it is easy to break the shaft, as long as the edge of the welded pipe mold becomes thicker, it can resist the elastic tension generated during the deformation of the steel belt, and it is not easy to be squeezed and cracked. Also, the surface hardness of the mold should be handled well, otherwise it will easily cause rapid wear of the mold, and even cause pipe surface strain.

There are still many requirements for the production of large diameter pipe welding molds. When you come to our Foshan Senwel Pipe Mold Machinery Co., Ltd. (Foshan Guanxiugang Trade Co., Ltd) we will communicate with you in detail. Our company independently develops, designs and produces large diameter pipe welding molds and pipe welding units, which can provide you with good service and one-stop solution to your procurement needs.

Next : Heat treatment method of pipe making mold Back

Home

- [2021.02.19]Technical requirements o…

- [2020.04.13]Adjustment mode of welde…

- [2021.02.18]Problems to be paid atte…

- [2021.02.17]Cooperation between stai…

- [2020.04.11]How to design welded pip…

- [2021.02.16]Notes on combination of …

- [2024.10.23]Effect of universal rack…

- [2024.10.18]Material selection of hi…

- [2022.12.16]It is recommended that t…

- [2021.02.16]How to improve the insta…

- [2024.10.15]Differentiation in desig…

- [2022.12.14]Why the welded pipe mech…

- [2022.12.12]Control system design of…

- [2020.04.11]Forming Method of Stainl…

- [2022.12.09]How to control the hardn…

- [2021.02.14]Straightening head insta…

- [2021.02.14]Effect of internal level…

- [2020.06.22]Arrangement of capillary…

- [2021.06.15]Thick pipe and thin pipe…

- [2021.02.12]Function of electromagne…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com