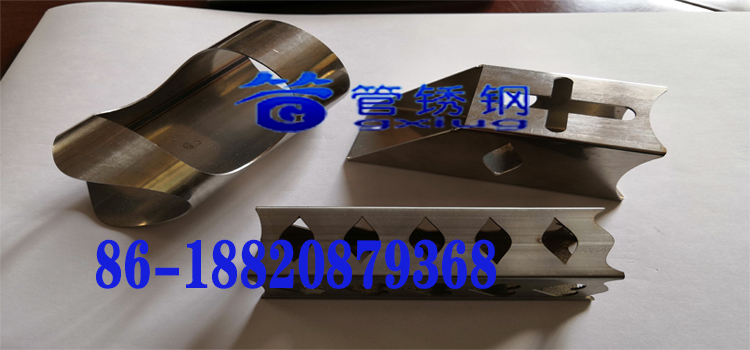

Since our company purchased the laser design last year, we have been able to process pipe diameters externally, not just the production of welded pipe machinery and welded pipe molds. In the laser cutting process, we are also seriously studying the advantages and disadvantages of laser drilling and traditional mechanical punching.

Laser tube cutting has the characteristics of faster speed, relatively accurate precision, and smoother nozzle. The traditional punching machine is relatively not so good, because it is stamped. And the nozzle is deformed a bit. In addition, for the speed, the mechanical punching can be designed to carry out multiple simultaneous, so the difference is not very big. It depends on the design.

Overall, I feel that laser cutting and hole drilling are still relatively good. If the financial pressure is low, it can be considered.Next : Different marking of welded pipe molds of different countries Back

Home

- [2021.11.02]How to select supporting…

- [2021.11.01]It is better to unify an…

- [2021.10.30]How to design the straig…

- [2021.02.06]Relationship between sta…

- [2020.06.16]Promotion of stainless s…

- [2021.10.29]How about the welding se…

- [2021.10.27]The difference between c…

- [2021.02.05]What kinds of pipes are …

- [2020.06.16]Decorative pipe welding …

- [2021.10.25]Why are some welded pipe…

- [2021.10.22]Cause analysis of unqual…

- [2021.10.21]How to choose the weldin…

- [2020.06.15]Thin wall stainless stee…

- [2021.10.20]Combination of welded pi…

- [2021.10.19]What are the classificat…

- [2021.10.18]Category of stainless st…

- [2021.02.03]Types of water pipe maki…

- [2020.06.15]Serious homogenization, …

- [2021.10.15]Introduction of Stainles…

- [2021.02.02]Selection of guardrail t…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com