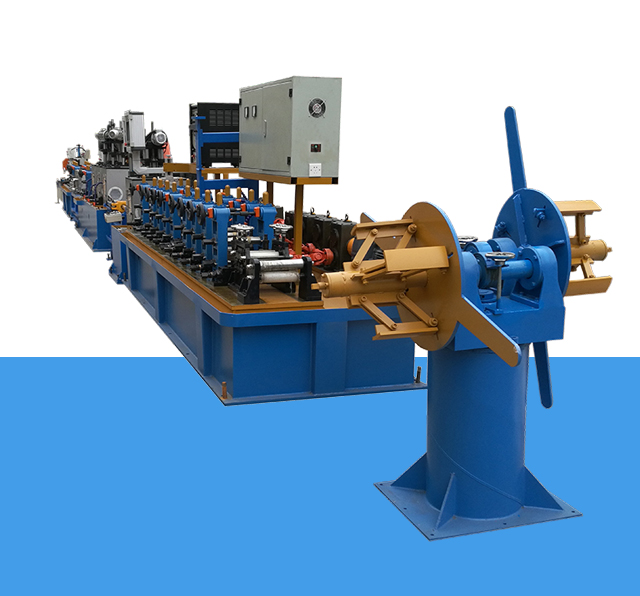

Industrial pipe welding machine

Tube material:Stainless Steel Titanium alloy Etc

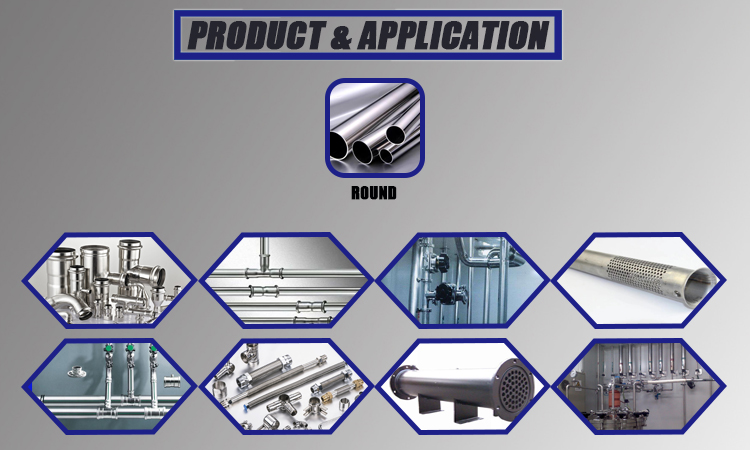

Pipe shape:Round Etc

Usage:Water pipe / fluid pipe / titanium pipe / petrochemical pipe / aerospace Automobile pipe /Drinking food grade pipe/hygienic grade pipes etc

Pipe diameter range: Φ 5-325mm

Wall thickness range: 0.15-10 mm

Product details

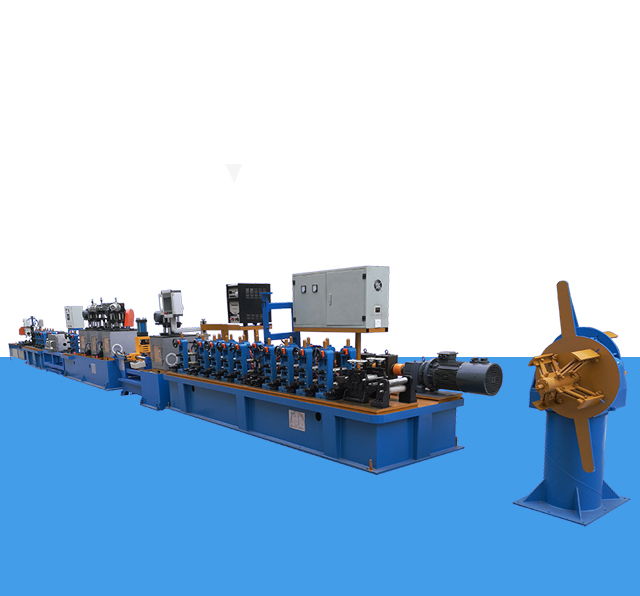

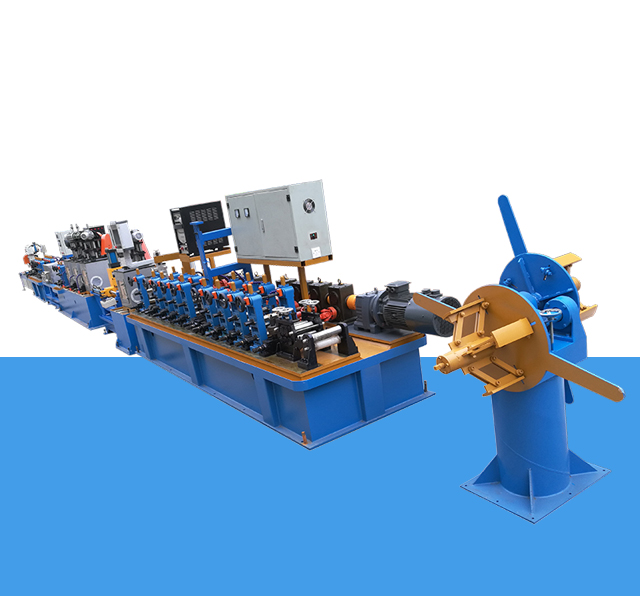

Industrial pipe welding machine

Product introduction

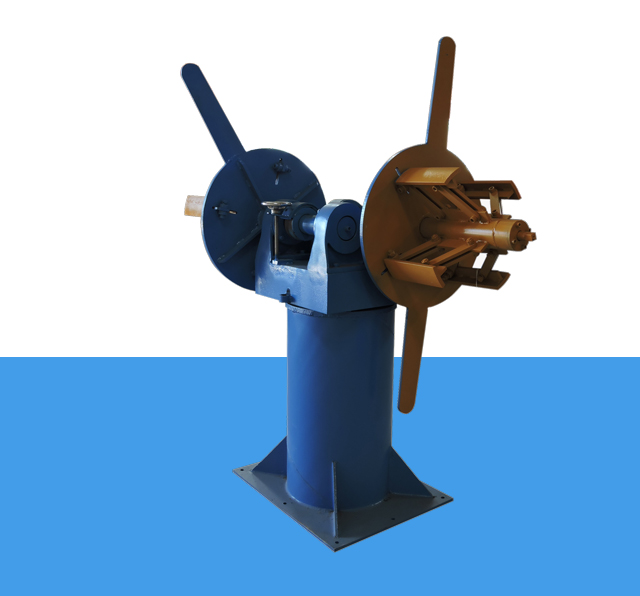

Precision industrial water pipe making machine tube mill is a metal pipe processing equipment specializing in the production of industrial pipes. It can be used in petrochemical, paper-making, food, beverage, medicine and other industries which require high fluid medium. Compared with the decoration machine, the difference between the industrial pipe making machine and the decoration machine is mainly reflected in the addition of welding seam processing and annealing equipment, making the industrial welded pipe closer to the seamless pipe.The hardness is reduced, the plasticity is enhanced, and the welded pipe performance is improved. For example, the production of drinking water pipes, food hygiene pipes, building pipes, automotive exhaust pipes, etc., industrial welded pipes with their easy access to raw materials, easy manufacturing process, simplified processing technology and other advantages can replace seamless steel pipes in a wider range,increase the choice of pipe use, reduce the cost of pipe use, and improve the economic efficiency of pipe enterprises.

Application range

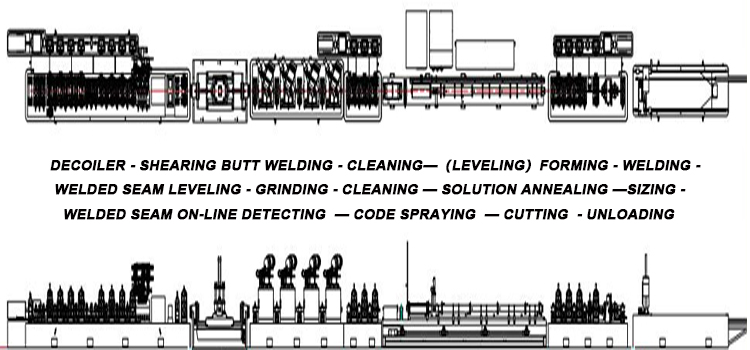

Production process

Model & Parameter

|

Industrial pipe welding tube making machine |

||||||

|

model |

Tube diameter range (mm) |

Wall thickness range (mm) |

Power of main motor (KW) |

Product tolerance (mm) |

||

|

GXG-10 |

Ø4—12 |

0.15—0.3 |

4.0 |

±0.01—0.05 |

||

|

GXG-20 |

Ø5—25 |

0.3—1.0 |

5.5 |

±0.01—0.05 |

||

|

GXG-30 |

Ø15.8—31.8 |

0.5—1.5 |

7.5 |

±0.05—0.10 |

||

|

GXG-40 |

Ø25.4—50.8 |

0.5—2.5 |

11.0 |

±0.05—0.10 |

||

|

GXG-50 |

Ø31.8—76.2 |

0.5—3.0 |

15.0 |

±0.05—0.15 |

||

|

GXG-60 |

Ø50.8—114.0 |

1.0—4.0 |

18.5 |

±0.10—0.25 |

||

|

GXG-70 |

Ø76.2—168 |

1.0—5.0 |

22.0 |

±0.15—0.30 |

||

|

GXG-80 |

Ø114.0—219.0 |

1.5—6.5 |

30.0 |

±0.20—0.30 |

||

|

GXG-90 |

Ø158.0—273.0 |

2.0—8.0 |

37.0 |

±0.25—0.35 |

||

|

GXG-100 |

Ø219.0—325.0 |

3.0—10.0 |

45.0 |

±0.30—0.50 |

||

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com

Consultation

Consultation