Fixture is a necessary part of the cutting machine of stainless steel pipe production line equipment. The design of the fixture is related to the use of cutting saw blade and the operation stability of the whole stainless steel pipe production line. Here we will talk about this small fixture. According to the pipe type and pipe diameter, the fixture can be divided into round pipe clamp, square pipe clamp, large caliber pipe clamp, small caliber pipe clamp, etc., and can also be divided into one fixture and split clamp. Today, we focus on the design of integrated fixture and split clamp.

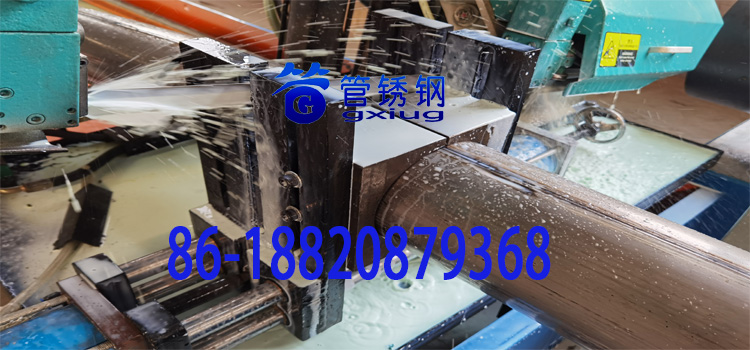

The design of integral fixture is the design of clamping pipe on both sides of the inside and outside. This design can make the stainless steel welding pipe production line cut the pipe more stable. Because of the internal and external clamping, the saw blade is only cut through the middle gap of the clamp, so the overall pipe is more stable and will not shake easily. This is also the use effect of the cutting precision and saw blade very good.

The split clamp is generally equipped with the band saw cutter of the large-diameter stainless steel welding pipe production line equipment, which is only installed on the inside of the cutting, and the outer side is not installed. In this way, the pipe is single side clamping, and the stability and precision of cutting are not as good as the one-sided clamping fixture, because the band saw will have obvious cutting deviation and swing. If the control is not good, the band saw blade will be provided Even a break can occur.

Whether it is one-piece or split clamp, the two-sided fixed mould shall be adopted on the installation mode, so that the fixture will not swing on the base of the cutting machine table of stainless steel welding pipe production line. Now you understand, will you choose?

Article by: stainless steel pipe production line equipment

http://www.fsgxiug.com Foshan Senwel technology - guanxiugang-gxiug finishing supply

Next : Design of mandrel for internal leveling equipment of stainless steel pipe weld bead Back

Home

- [2021.08.07]High frequency welded pi…

- [2021.08.06]Selection of material st…

- [2020.06.18]The advantages and disad…

- [2021.08.05]Production cycle control…

- [2021.03.30]Industrial pipe welding …

- [2021.08.04]How to choose the materi…

- [2020.06.17]Different marking of wel…

- [2021.08.03]How to develop stainless…

- [2021.08.02]How to select on-line an…

- [2020.12.08]what is included in the …

- [2021.07.31]Senwel technology pipe w…

- [2021.03.27]Different welded pipes h…

- [2021.07.30]How is the Stainless ste…

- [2021.07.29]Significance of on-line …

- [2021.03.26]The function of welding …

- [2021.07.28]Do stainless steel welde…

- [2021.07.27]What if the stainless st…

- [2021.03.25]Application of H13 mater…

- [2021.07.26]Most pipe welding machin…

- [2021.07.24]How to calculate the wei…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com